In-Service Corrosion Mapping & Thickness Profiling

Westech Inspection, Inc. utilizes advanced automated ultrasonic scanning systems to perform high-resolution C-Scan corrosion mapping on tanks, pressure vessels, and piping while equipment remains in service.

Our computer-controlled magnetic crawler system provides over 250 lbs of magnetic holding force and can be configured for multiple geometries and orientations. Because the crawler can be remotely steered, large inspection areas can be examined without scaffolding, rope access, or extensive entry requirements.

The result is a safer inspection with significantly more data and higher reliability compared to manual spot ultrasonic thickness readings.

Why Automated C-Scan Instead of Manual UT?

Traditional thickness readings provide isolated data points. Automated scanning produces a complete mapped profile of the component.

Benefits include:

-

Large area corrosion mapping rather than isolated spot readings

-

Identification of localized corrosion and pitting

-

Improved remaining life calculations

-

Reduced access requirements and downtime

-

Digital records for trending and future comparison

This allows owners and engineers to make maintenance decisions based on actual condition rather than limited sampling.

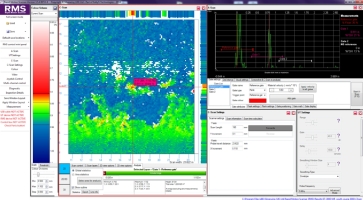

High-Resolution Imaging Capabilities

Standard Resolution Scanning

0.25 in × 0.25 in grid spacing

Rapid coverage of large surface areas for general corrosion assessment and screening.

High-Resolution Scanning

0.05 in × 0.05 in grid spacing

Detailed imaging capable of revealing fine corrosion contours, localized pitting, and small defect features.

B-Scan & Data Interpretation

Each C-Scan image is supported by full B-Scan cross-sectional data.

By scrolling through the collected scan lines, our technicians can:

-

Classify corrosion mechanisms

-

Differentiate laminations from metal loss

-

Accurately size defects

-

Verify minimum thickness locations

-

Confirm data reliability for engineering calculations

This is critical when performing remaining life or MAWP calculations, where inaccurate readings can lead to overly conservative repairs — or unsafe continued operation.

Typical Applications

-

Pressure vessel shell corrosion mapping

-

Tank shell and floor plate evaluation

-

Exchanger shell internal corrosion

-

Piping corrosion under insulation screening areas

-

Fitness-for-service assessments

Reliable Data for Engineering Decisions

Automated ultrasonic mapping provides the detailed thickness profile required for defensible engineering evaluations and mechanical integrity programs. Instead of estimating condition between measurement points, you receive a full visual representation of the component’s actual remaining material.