[vc_row][vc_column width=”1/1″][vc_column_text]

In-service Automated Ultrasonic C-Scan Imaging

Westech Inspection. Inc. uses a powerful automated ultrasonic scanning system. Our system is a computer controlled magnetic crawler system with over 250 pounds of holding strength and is configurable for many different applications.

Combined with Westech Inspection’s diversified experience in Automated Ultrasonics we can provide the most Cost Effective C-scan imaging of various types of structures i.e. tanks, pressure vessels, and piping. With the ability to steer our crawler we can save the cost of erecting expensive scaffolding to gain access.The overall result of utilizing this cost-effective system is that it allows us to collect More Data Of A Higher Quality that shows more than just spot readings taken by manual ultrasonic testing.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/3″][vc_single_image image=”399″ border_color=”grey” img_link_large=”” img_link_target=”_self” img_size=”full” alignment=”center”][/vc_column][vc_column width=”2/3″][vc_column_text]

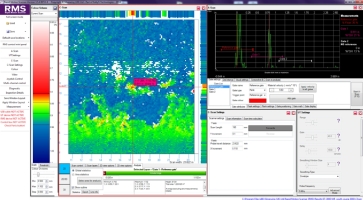

Ultrasonic C-Scan Imaging of Exchanger Shell with Internal Corrosion

[/vc_column_text][vc_column_text]With Standard Resolution 0.25” x 0.25” large areas can be scanned in a minimum amount of time.

With High Resolution 0.05” x 0.05” the details of the corrosion are easily seen. This high quality C-Scan image can reveal the finest contours and characteristics of any indications found. Our

B-Scan feature is a powerful tool when it comes to corrosion analysis.

The ability to scroll through the B-Scans that make up the C-Scan image gives the operator the ability to accurately classify the type and size of defects found while also giving a clear view of the inside plate profile. In the hands of a skilled operator this tool provides a safeguard against false thickness data from laminations or inclusions. Engineering calculations for remaining life expectancies or maximum allowable working pressure (MAWP) requires very accurate thickness data.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/1″][vc_column_text]

For more information please call us @ 302.737.5370 or Click Here

[/vc_column_text][vc_single_image image=”401″ border_color=”grey” img_link_large=”” img_link_target=”_self” img_size=”large” alignment=”center”][/vc_column][/vc_row]